Production Surveillance

Real-time flow data accuracy

Reduced remediation time for ‘problem-wells’

Oil wells prioritized for production efficiency

Digital operations in a production environment collect huge amounts of data and information from sensors installed from the reservoir all the way to the refineries and distribution centers. It’s often difficult to fully realize the value of this data due to lack of resources and technology - for example, most operators can only test their wells on a monthly basis, creating a clear mismatch between real-time equipment data and production data.

Optima’s calibration system automates the periodic validation of actual well production data, ensuring that you have the most up-to-date information possible to make informed decisions. Real-time asset management and flow estimation features, along with an intelligent alarm system, allow you to maximize production whilst ensuring your assets are working optimally. This ensures you can leverage your data for maximum revenue growth whilst significantly reducing maintenance costs.

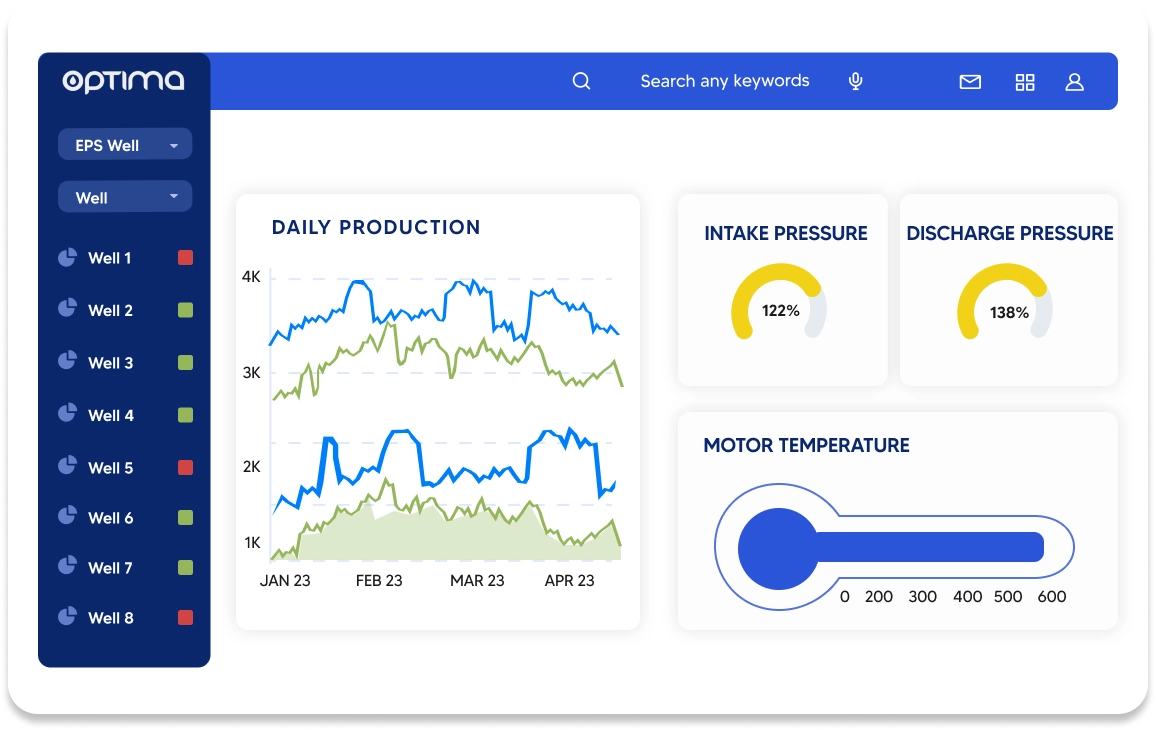

Optima for real-time well performance tracking

Optima's Production Surveillance features allow real-time asset management with a customized intelligent alarm system designed to increase production while protecting assets. Machine learning-driven event detection features accurately detect issues that could result in equipment damage, and the failure prevention algorithm also automatically prioritizes wells that may fail in the near future.

Flow data powered by the Virtual Flow Meter (VFM) module offers virtual real-time flow estimations with over 95% accuracy. Our technology empowers you to stay ahead of the curve, making informed decisions that drive performance and deliver results.

Discover Related Solutions- Machine Learning

- Maximum Efficiency

- High Accuracy rate

- Event detection

- Production Surveillance

- Real-time analysis

- Informed decisions

- Production enhancement

- Operations optimization

- Virtual Flow Meter

Get ahead of the curve

- Over 95% accuracy for real-time data flows - ensure smooth production with precision

- Prioritize production enhancement candidates better - boost productivity with targeted improvements

- Faster remediation of problem wells - minimize downtime and keep operations running smoothly

- Reduce reliance on well tests for problem diagnosis - timely insights for proactive field/well management

Sharing our expertise

Get the latest industry insights with our extensive range of blogs and whitepapers.

Let’s Talk

Fill in your details and our team will get in touch.