Artificial Lift Lifecycle Management

Enhanced traceability of Artificial Lift (AL) system planning and ops

Optimized equipment design for oil well and operation conditions

Improved run life for oil wells and fields

Tracking the lifecycle of ESP equipment has traditionally presented significant challenges for both operators and service companies. A precise understanding of the operating environment and conditions critical for improving runlife, avoiding premature equipment failures, and improving overall economics by better matching equipment specifications to well and operating conditions. Additionally, tracking ESP cable usage poses a unique challenge due to the need for cutting, splicing, reusing, or reinstalling cables in multiple runs. Considering that ESP cable represents 40% of the total ESP system cost, effective management is crucial to minimize expenses.

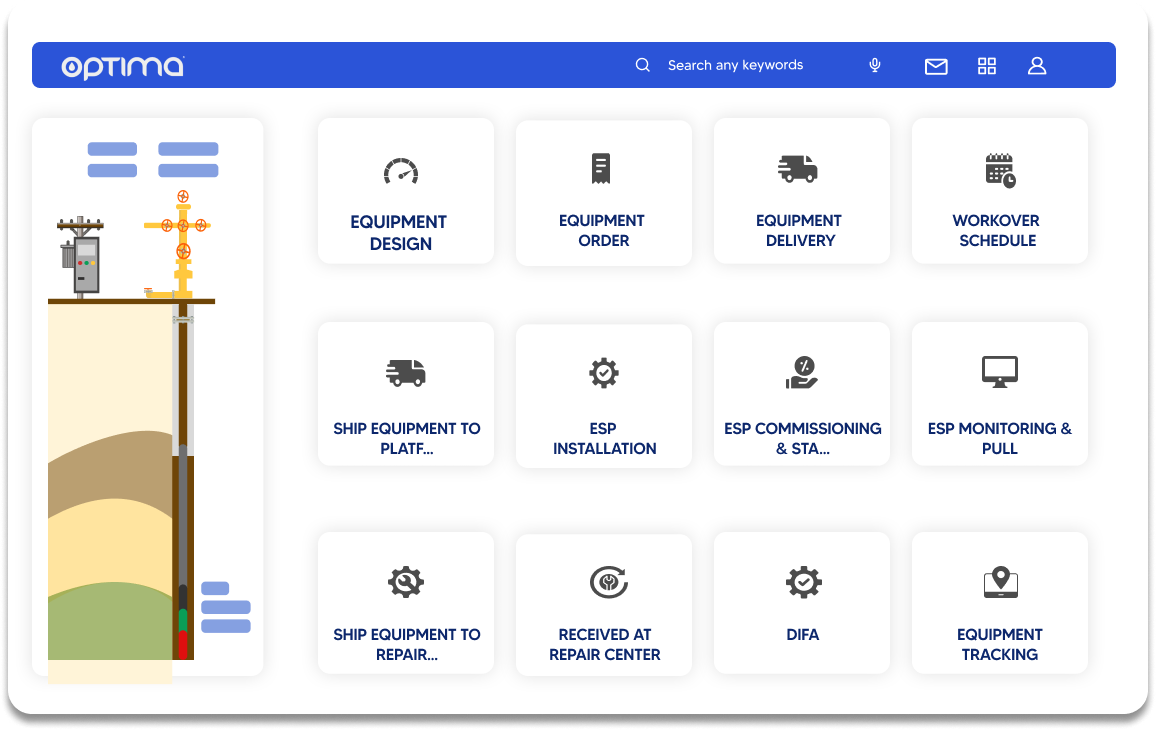

Managing the ESP lifecycle is a high priority for operators and ESP suppliers alike to maximize utilization, minimize slow-moving inventory and lead time, and improve forecasting accuracy. By addressing these challenges, operators can improve efficiency and performance while reducing costs; Optima’s Artificial Lift Lifecycle Management module is an ideal solution to these obstacles. Operation managers benefit from automated traceability delivery workflow, from contract signature and reception of PO to the installation and reception of used equipment back at the base. A key solution is a single platform like Optima that integrates sales, engineering, manufacturing, planning, field operations, and reception functions.

Optima for maximizing ESP life cycle

Optima’s Artificial Lift Lifecycle Management module offers a fully customized, complete, and integrated workflow that tracks the life of a well, from the design of the equipment through its replacement cycles. Operators can accurately track new and used cable as it moves along the typical operation cycle, resulting in better inventory management, from PO to disposal.

Tracking the precise operational environment, including loading, restarts, temperature, and well conditions allows the operator to find the best-fit design that will meet key objectives, including re-use, repair, and splice and retirement field guidelines.

Discover Related Solutions- Customizable System

- Integrated Workflows

- Inventory Management

- Data Visibility

- Accurate Forecasting

- Informed Decisions

- Greater Efficiency

- Preventing Failures

- Reduced Lead Times

- Automated Traceability

Get ahead of the curve

- Minimize losses and ensure efficient re-stocking of unused or backup cable by accurately quantifying and tracing scrap pieces

- Optimize inventory levels and ordering points through effective inventory management strategies, leading to cost savings

- Tailored equipment designs and specifications to specific well and operating conditions, maximizing performance and efficiency

- Lower operational expenses by optimizing design and operational parameters, resulting in improved overall economics

- Improve inventory management and reduce requirements through accurate forecasting, avoiding unnecessary over-design of technical specifications, and optimizing re-utilization guidelines without compromising runlife

Sharing our expertise

Get the latest industry insights with our extensive range of blogs and whitepapers.

Let’s Talk

Fill in your details and our team will get in touch.